SAXUM's CEO, Dr Eng Guillermo Etse, presented a Technical Talk named "Moderation and analysis of seismic dynamic interaction in soil foundation-mill systems" within the framework of the XXVII Argentine Conference on Structural Engineering.

ABSTRACT:

The mineral processing industry such as metalliferous mineral mining plants (copper, gold, silver, etc.) and cement plants, require grinding systems with high production capacity within their manufacturing process. Grinding of 100,000 ton/day capacity in mining plants, or greater, are currently a standard requirement. These high production capacities make grinding systems critical components for the operation of mineral processing plants since an eventual stoppage due to failure or collapse implies a significant economic loss.

From the point of view of structural capacities and the design of their foundations, grinding plants demand equipment whose characteristics involve diverse and considerably difficult complexities. The grinding systems of mining plants, at different levels, use ball and semi-autogenous (SAG) mills. Due to their considerable dimensions and dynamic force involved, these mills require large foundations, which develop an intense dynamic interaction with the surrounding soils.

In this aspect, a critical element to consider is the air gap or light between the stator and the mill, which surrounds almost the entire perimeter of the mill and has millimetre dimensions. Therefore, an eventual imbalance or uncontrolled vibration of the mill could lead to impacts between it and the stator, and irreversible damage to it, as has already happened in some mining plants. As a consequence, two difficulties arise when designing foundations for ball and SAG mills. On the one hand, that the dynamic behaviour of the mill-foundation-soil system be such that controlled vibrations result in the foundation avoiding affecting the operation of the mill itself and, in parallel, that the level of vibrations transmitted to the foundation soils does not affect the operation of other mills and dynamic equipment in the vicinity. On the other hand, in the case of mining plants located in areas with high seismic risk, the design of these foundations must appropriately resist the movements and additional efforts imposed by the seismic action to avoid affecting the air gap and generating damage to the stator, windmill and the components of their supports.

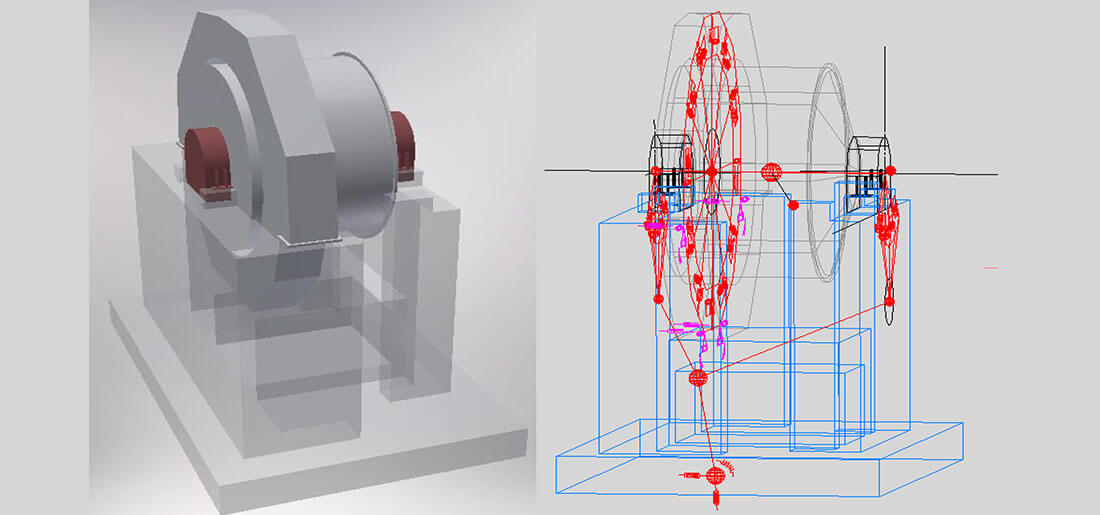

To carry out a precise dynamic and seismic analysis of structural systems of ball and SAG mills, it is possible to proceed through detailed modelling of the set of elements that compose them, the most important being the foundation, the stator, the structure of the mill with the grinding material, and the supports of the mill and stator in the foundation. According to the experience of the authors of this work, precisely determining all the parameters of the stator, of the supports and of the mill itself, essential for advanced modelling, is highly complex or impossible, mainly due to conflicts with the intellectual property of the manufacturers of mills and stators. However, specific data can be obtained from the manufacturers, such as the stiffness of supports, and the sections and masses of the mill and the stator, which in principle do not violate the confidentiality of your information.

In this presentation and based on this minimal and accessible information, a simplified and efficient modelling procedure is presented to analyze the fundamental dynamic properties of the mill-foundation-soil system and, in particular, to carry out a sufficiently precise structural verification of the mill, stator, air-gap, support of the mill towards the foundation, and the design of the foundations of these mills against severe seismic dynamic actions. Likewise, numerical predictions of the seismic performance of real dynamic systems corresponding to a ball mill and a SAG mill are presented by considering their main components (mill, stator, mill supports and foundation), their interfaces and the interaction of the soil with the foundation, with the aim of reducing the level of complexity of the modelling towards a simplified model.

The results show the accuracy and efficiency of the proposed simplified modelling procedure and the feasibility of its use for the analysis of the dynamic behaviour of foundation systems of grinding and crushing equipment.

Latest news

- The Story Behind the Partnership – SAXUM/Lycopodium 6 August, 2025

- SAXUM´s Newsletter Issue #251 – May 2025 21 May, 2025

- SAXUM Joins Forces with Lycopodium 18 February, 2025

- SAXUM´s Newsletter Issue #242 – December 2024 9 December, 2024

- SAXUM´s Newsletter Issue #241 – May 2024 1 May, 2024

- SAXUM´s Newsletter Issue #232 – Dec 2023 14 November, 2023

Categories

- Articles (1)

- Connection (13)

- Events (2)

- News (11)

- Sin categoría (7)

You must be logged in to post a comment.