Balance of Plant Engineering & Design for Kwinana Grinding Plant Upgrade at Western Australia

Cockburn Cement Limited (CCL) is an Adbri Limited Company, which is one of Australia’s pioneering and leading producer of construction materials and industrial minerals. The Kwinana Upgrade Project is a subtantial investment to consolidate Adbri’s two existing Western Australian cement production sites (Munster and Kwinana) into a single operation servicing the Western Australia market.

The Project includes new grinding circuits, raw material storage and a reclamation system designed for the production of a number of different cement products for the local market.

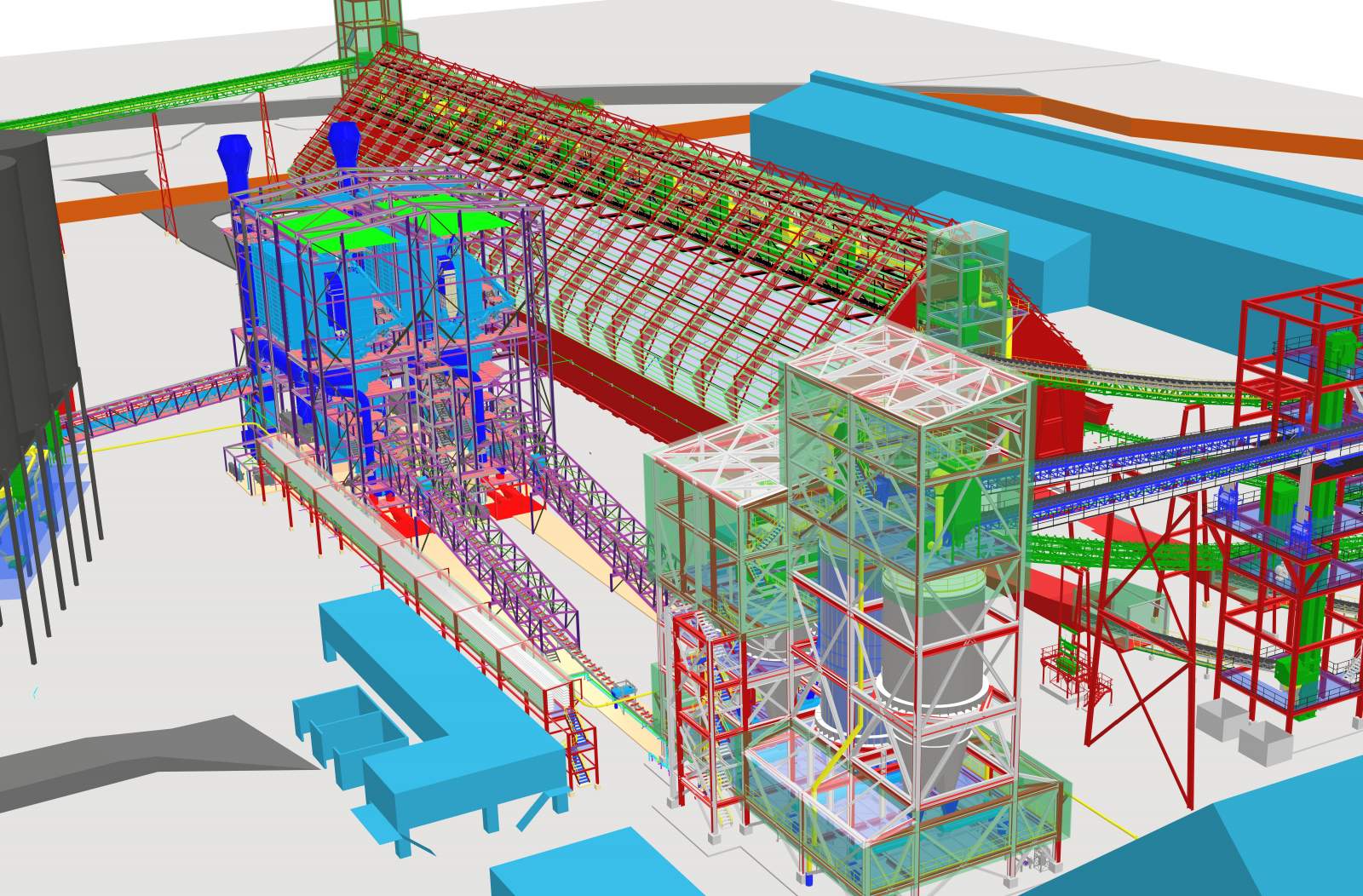

SAXUM is currently developing the Balance of Plant (excluding Grinding Circuit) engineering and design solution for the Kwinana Grinding Plant Upgrade. The scope of works includes process, mechanical, piping, civil, structural, electrical, and instrumentation engineering designs as required for the manufacture, supply, construction and operation of the grinding and storage upgrade works to the CCL Kwinana project, it covers all engineering disciplines and designs based in Australian Codes.

One of the key objectives of the upgrade will be the ability to receive and store bulk raw materials, directly from Fremantle Port Authority’s (FPA), Kwinana Bulk Terminal, via a new raw materials feed conveying system to a covered longitudinal storage shed of 110,000 ton capacity. The facility will incorporate 2 new 100 tph ball mill grinding circuits feeding into 6 new 3,500 ton finished product silos with integrated truck loading.

Engineering deliverables by SAXUM include; issued for construction documents/drawings, technical specifications, tender packages for free issued equipment, structural fabrication details and construction drawing and model aids. SAXUM will also perform Engineering support for site preparation and construction activities, combined with site supervision. SAXUM will also provide assistance for HAZOP work shops.

SAXUM´s main objective is the design, engineering and integration of: Clinker Transport handling and Receival; Clinker Storage and Reclaim System, Feed & Grinding Mill Circuit, integration to existing plant and storage facility; Finished Products Silos and Blending & Despatch System and Auxiliary Services (water, fire protection, air compressed power).

SAXUM is focused on the incorporation of design features that ensure the plant and equipment is safe, efficient, reliable, cost effective, performs to the desired production specifications and considers constructability. These features will result in appropriate HS&E performance and a more energy efficient solution.

Trade-off Study and Logistical Analysis for Kachi Lithium Project

Lake Resources is an Australian mining company focused on the development of lithium projects. Lake’s flagship Kachi Project is located in the Puna region of the Catamarca Province, Argentina, within the well-known Lithium Triangle.

In November 2018, Lake announced a maiden JORC resource at Kachi of 4.4 million tonnes (Mt) of contained lithium carbonate equivalent (LCE), and an exploration target ranging between 8-17Mt of LCE. This ranks Kachi as one of the world’s top 10 brine resources.

Currently, Lake is involved in the development of a Feasibility Study (FS) for the project, and as part of this study, SAXUM developed a comprehensive logistic assessment regarding the construction and operational phases of the project/mine.

The objective of this logistic study is to provide relevant information, alternatives, and conclusions to Lake Resources for the Project Development and the Mine Operation that will allow them to determine the most convenient and cost-effective alternative and strategy for the import of main equipment during the construction phase of the project, as well as for the import, export and warehousing of reagents and final products during the plant operation.

SAXUM, through its team of experienced professionals in mining operations and logistics in Argentina, is performing this project within the highest quality standards.

Conceptual and Basic Engineering of two greenfield cement plants in Brazil - CSN

Companhia Siderúrgica Nacional (CSN) is a company that operates in five segments of the economy, Steel, Mining, Cement, Energy and Logistics. In 2009, CSN started producing Cement in Brazil. SAXUM has a long relationship with CSN and has participated in different projects, ranging from cement grinding to the new clinker and cement production line at Arcos.

On this occasion, CSN once again trusted SAXUM capabilities and services for the development of Conceptual and Basic Engineering and support for the EIA/RIMA regarding two greenfield cement plants in different regions of Brazil, with capacity of 4,500 and 7,200 tpd. The engineering services of SAXUM encompass all technical disciplines, from process and mechanical to civil/structural and electrical/instrumentation/automation.

In addition to engineering development, different trade-off studies will be carried out to choose the best/optimal alternatives from the engineering and construction point of view, which will allow us to accurately estimate the CAPEX required for the implementation of new CSN units. SAXUM experience in similar project scopes is crucial for accomplishing CSN objectives for these greenfield projects related to clinker and cement production plants.

EPCM services for a Greenfield Lithium Carbonate Production Plant - Minera EXAR

Minera EXAR is developing the Cauchari-Olaroz Lithium Project, located in the Province of Jujuy, in the Northwestern Region of Argentina, in an area known as the Lithium Triangle. The project is due to be in production during Q2-2022. With a total investment of over 600 million dollars, the plant will produce 40 KTPA of “Battery Grade” Lithium Carbonate.

Following the results of the Due Diligence developed by SAXUM in early 2021, EXAR has engaged our company to provide Engineering, Procurement and Construction Management Services (EPCM), to allow EXAR to expedite the completion of critical project tasks and activities.

Particularly, SAXUM is providing the following services to EXAR:

- Engineering: SAXUM has been assigned with a complete team of Senior Structural, Mechanical, Piping, Electrical, and Instrumentation Engineers and Drafters, to review the pending project engineering, and to complete its development to allow for the procurement and construction schedules to be achieved.

- Procurement Services: SAXUM procurement team was engaged to take leadership of the Project procurement activities, particularly buying, expediting and follow up of shop fabrications, to expedite all pending items in the project critical path.

- Construction Management: SAXUM teams as been involved in the Project Construction Management Team, providing the following Services:

- Site Engineering Team

- Contracts Management and Administration

- Vendors Coordination

A total of 24 SAXUM personnel are currently involved in the EXAR Cauchari-Olaroz Project Development.

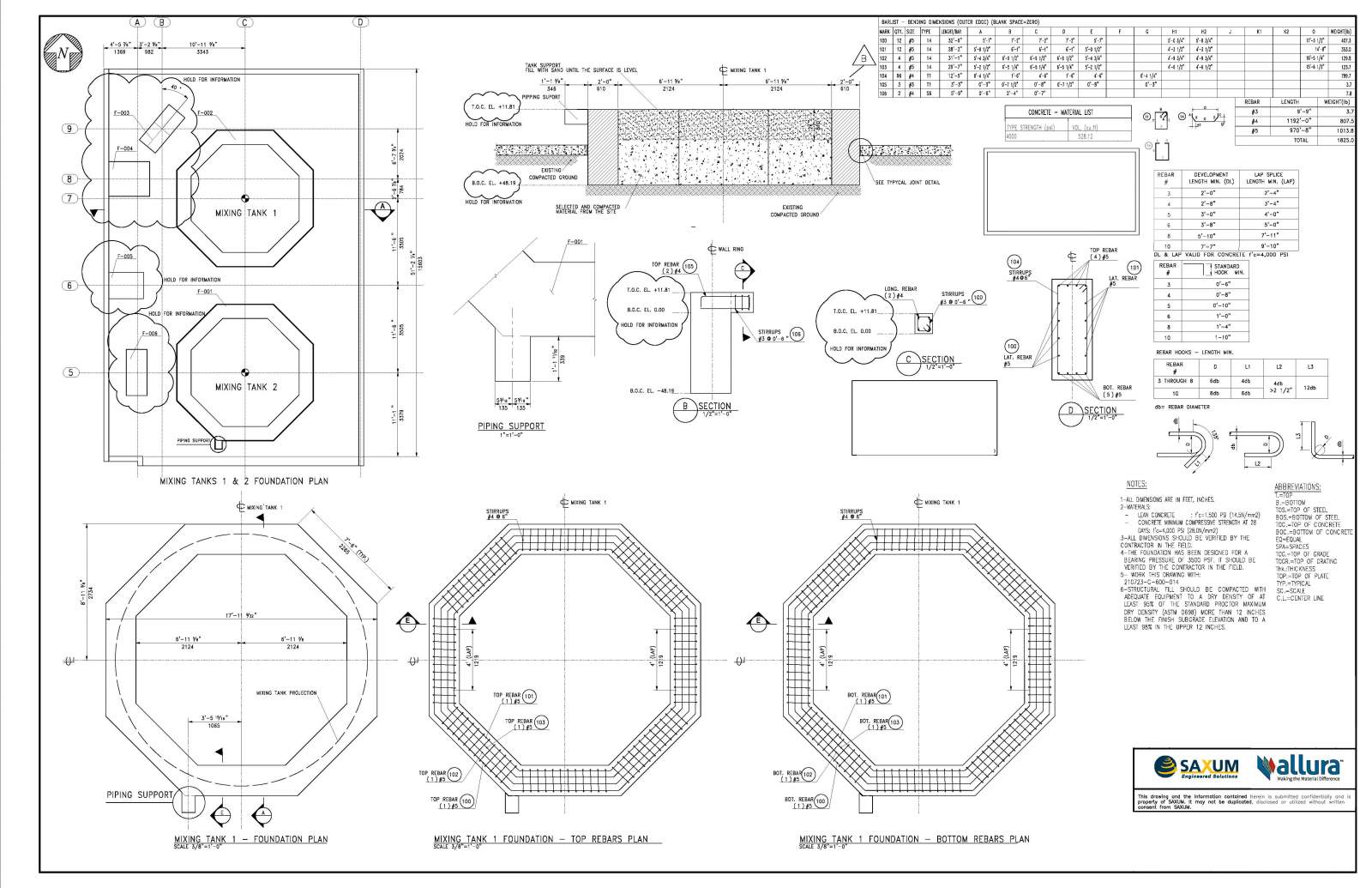

Basic and Detailed Engineering for Allura's Sand Grinding Project in Roaring River, North Carolina

The Allura/Elementia Roaring River Project located in North Carolina, USA, consists of a wet sand grinding plant to obtain sand with a certain specific and uniform size particle/granulometry. The process consists of a sand reception hopper which will be fed by a front-end loader or other means and a hopper below, which will feed a belt that will transport the material to the mill. The milling will be wet, using a ball mill and will be in a closed circuit with recirculation.

The material at the exit of the mill will be a pulp (solid + liquid) which will be fed through a pulp pump to a classifying hydro-cyclone, in which the material with the appropriate size/fineness will go to the next phase of the process and the coarse material will be returned to the mill. After the hydro-cyclone, the pulp will be sent to a thickener tank, where the maximum amount of water will be removed from the pulp to obtain the final product sought. A European OEM has been selected for the ball mill and local/USA equipment suppliers for the rest of the equipment.

For this project, Allura has selected SAXUM Engineering LLC based in Irving, Texas/USA, to perform the Basic and Detailed Engineering, including Civil/Structural, Mechanical/Piping, and Electrical/Instrumentation & Controls, as well as layout analysis.

SAXUM will integrate the complete project in a single 3D model, bringing together all Civil, Structural, Mechanical, Piping, E&I, and equipment. This will allow for a full and comprehensive project review and early detection of possible interferences between structures, equipment, rack supports, etc.

For this project, SAXUM has assigned an experienced team of engineers and designers. SAXUM’s responsibility in this Allura project includes the PE stamping and sign-off by registered professionals in the state of North Carolina.

SAXUM will also assist Allura during the construction phase of this project.

SAXUM´s Commercial Manager, Ms. Constanza Unzaga

Constanza is an Industrial Engineer from the National University of Tucuman, Argentina, she also has an M.Eng. Project Management degree obtained in Hochschule Biberach in Germany. Also, she has recently gained her Project Management Professional Certificate (PMP).

As SAXUM´s Commercial Manager Constanza is in charge of the coordination and management of all commercial actions carried out through all SAXUM companies in Argentina, Brazil, the USA and Australia. Also, she has extended experience working with multicultural, multidisciplinary and intercompany teams of professionals for engineering and construction management projects. Constanza has strong leadership and a team working profile, which is highly necessary for this position.

At the same time, Constanza has experience as a Project Manager and therefore led several projects around the world including Argentina, Bolivia, Australia, and others.

Latest news

- The Story Behind the Partnership – SAXUM/Lycopodium 6 August, 2025

- SAXUM´s Newsletter Issue #251 – May 2025 21 May, 2025

- SAXUM Joins Forces with Lycopodium 18 February, 2025

- SAXUM´s Newsletter Issue #242 – December 2024 9 December, 2024

- SAXUM´s Newsletter Issue #241 – May 2024 1 May, 2024

- SAXUM´s Newsletter Issue #232 – Dec 2023 14 November, 2023

Categories

- Articles (1)

- Connection (13)

- Events (2)

- News (11)

- Sin categoría (7)

You must be logged in to post a comment.