Enhancing Infrastructure: SAXUM Drives Expansion at CRUZ AZUL's Oaxaca Plant

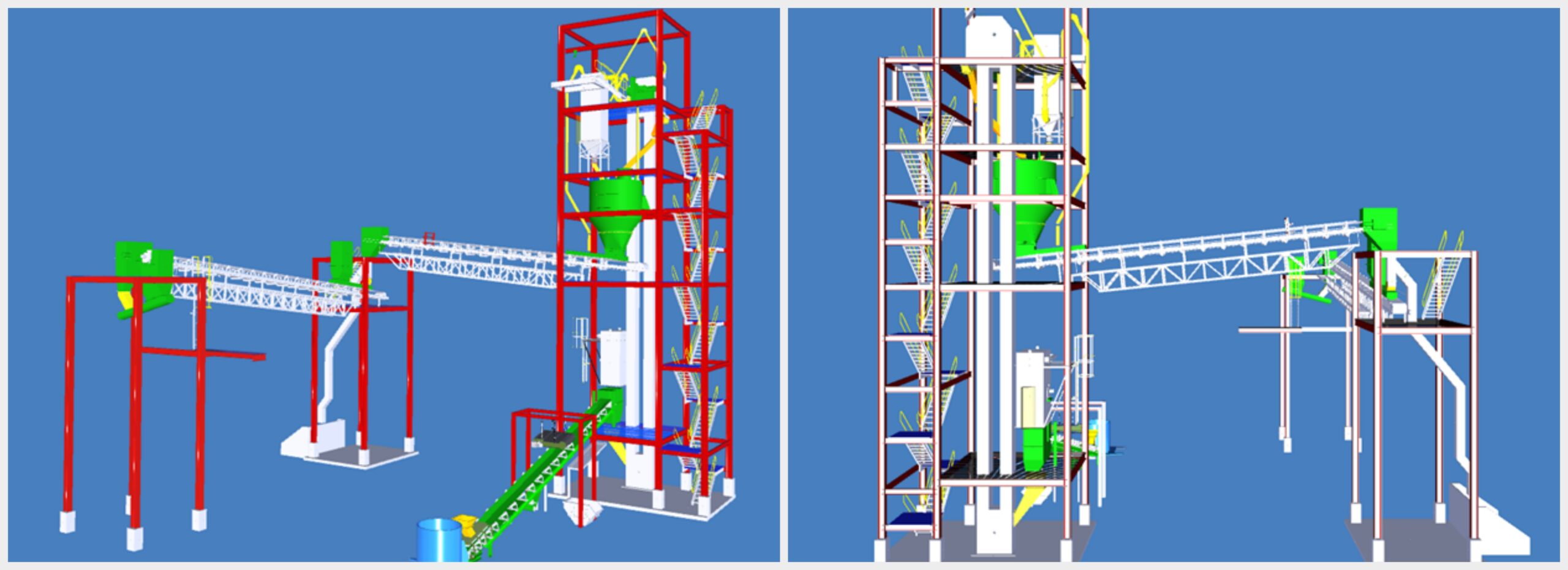

Cooperativa La CRUZ AZUL, S.C.L. (CRUZ AZUL), a leader in Mexico’s construction industry since 1881, is undertaking an ambitious expansion of its Cement Grinding Capacity with the installation of Mill No. 15 at its Lagunas, Oaxaca plant. To support this project, SAXUM provided Engineering and Integration Services, ensuring the project's quality and adherence to its timeline.

At SAXUM, our multidisciplinary team is committed to delivering high-quality solutions that guarantee efficiency, compatibility, and excellence in project execution. For the Cement Mill No. 15 project, SAXUM’s scope of work spans several critical areas: 511: Mill 15 Feeding System; 541: Cement Transport; 741: Compressor Room; 591: Electrical; Substation for Mill 15; 531: Cement Mill.

SAXUM's services include:

- Instrumentation and Control Integration Engineering

- Mechanical Integration Engineering, for piping, chutes, and dedusting ducts

- Interface and Communication Management with suppliers

- Design Integration with the existing equipment in the plant.

These services support project scope not included in the OEM deliverables enabling a fully integrated and high-quality project. SAXUM’s role also ensures swift and detailed responses to CRUZ AZUL’s requests for information, supporting the project’s success and schedule objectives.

SAXUM is honoured to collaborate with CRUZ AZUL, contributing to the growth of one of Mexico’s most respected cement producers.

Advancing the Rincon Lithium Project: Strategic Development Stages and Key Milestones

Argosy Minerals Limited, an Australian Securities Exchange-listed company, via Puna Mining S.A., is advancing the Rincon Lithium Project in Salta Province, Argentina. The project is strategically located within the world-renowned “Lithium Triangle,” home to some of the largest lithium resources globally.

Currently, efforts are concentrated on Stage 3 of the project, which aims to establish a 12,000-tonne-per-annum lithium carbonate production facility. SAXUM is proudly involved in this development through Early Contractor Involvement (ECI) and Technical Services.

SAXUM’s contributions are pivotal in expediting the project timeline, supporting the completion of the Definitive Feasibility Study (DFS), and achieving the Final Investment Decision (FID). This schedule aligns with key milestones, including early site works, procurement of long-lead items, front-end engineering design (FEED), and commencement of construction.

VCNA Advances Mill Efficiency with Innovative Engineering Upgrade at St Marys Plant

Votorantim Cimentos North America (from now on VCNA) is part of Votorantim Cimentos, one of the largest cement producers in Brazil, and the seventh largest in the world. The company was founded in the city of Votorantim in 1933 and is headquartered in São Paulo, and the Technical Center is located in the city of Curitiba, Paraná. VCNA began in 2001 with the acquisition of St Marys Cement and have continued to expand.

VCNA is planning to install a Raw Mill Recirculation system for their existing vertical raw mill at their St Marys Cement Plant, located in Ontario, Canada in order to increase the efficiency of the mill. VCNA required the assistance of an experienced Engineering Company with knowledge of cement technology and the industry to perform multidisciplinary conceptual and basic engineering designs for the new facility.

SAXUM completed the basic engineering and supported in evaluating bids and developing the CAPEX estimation. Recently VCNA has awarded SAXUM a contract to perform the detailed engineering that will be used to complete the construction work.

SAXUM in currently completing the designs related to process, mechanical, and structural engineering. SAXUM's scope of work in this project includes the mechanical and construction bid packages, the BOQs, and the support to VCNA during the construction phase.

BEUMER's Overland Conveyor Project Elevated by SAXUM's Engineering Expertise

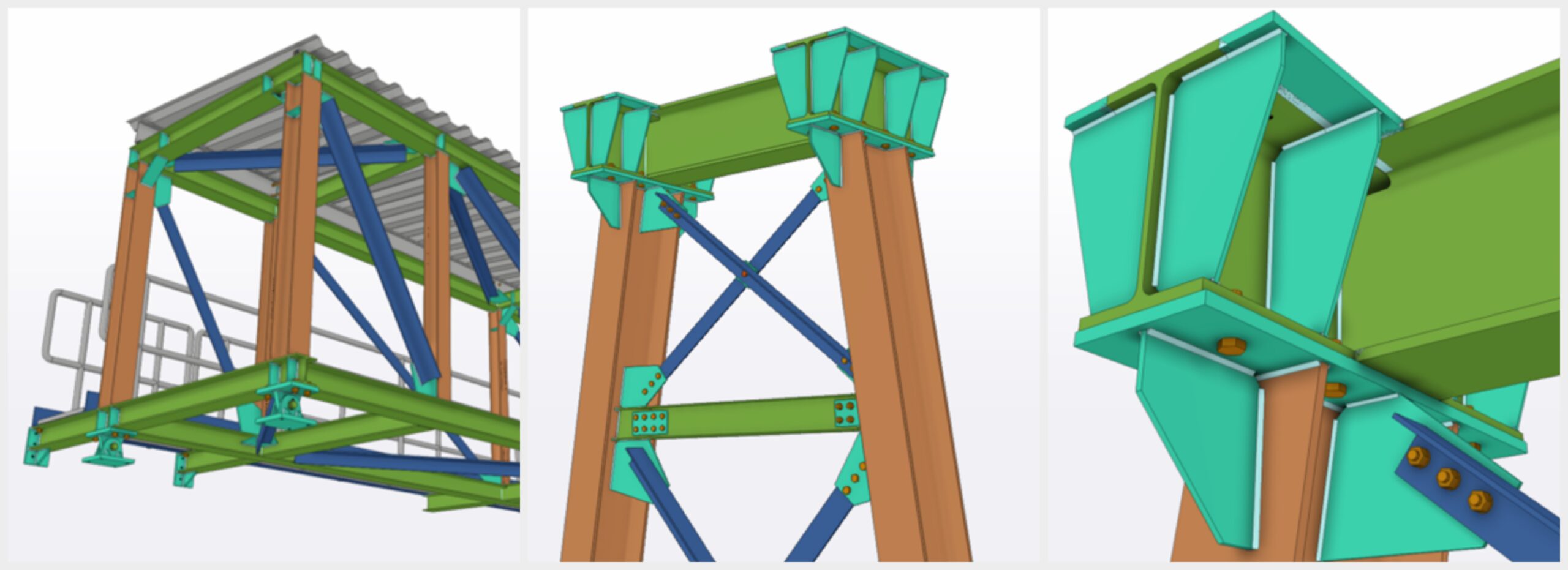

SAXUM was selected by BEUMER Group to provide comprehensive structural engineering and support services for the Overland Conveyor Upgrade project at Warrior Met Coal, Inc., located in Brookwood, Alabama. This ambitious project involved the design and development of a new overland conveyor system tailored to meet specific operational demands.

The BEUMER conveyor system features a single-flight curved overland conveyor designed to transport 1,500 Short Ton Per Hour (STPH). To optimize performance, the system includes nine load-sharing drives which help to moderate belt tension. The conveyor's design also incorporates an elevated track for nearly half of its 14 km length, strategically planned to traverse natural terrain with minimal earthwork and structural footprint.

Throughout the project, SAXUM delivered both basic and detailed structural engineering services. During the Basic Engineering phase, a Level 1 3D model was developed using BEUMER’s templates. This model underwent significant modifications to align with the specifications of Warrior Met Coal, as well as local and state codes and regulations. The detailed engineering phase expanded this model into a comprehensive 3D version, from which shop drawings for the external fabricator were derived.

SAXUM's team, including licensed PE Civil Engineers, worked in close coordination with BEUMER's structural engineers and designers to ensure high precision and compliance in model development. This collaboration ensured adherence to all relevant building codes and MSHA (Mine Safety and Health Administration) regulations.

The responsibility of overseeing the entire 3D modeling process was assumed by SAXUM, facilitating the efficient management of project specifications and construction challenges.

Key Deliverables:

- Basic and Detailed 3D Models: Created detailed models that served as a primary reference for fabrication and construction phases.

- Assembly Models: Produced clear and precise assembly models to aid in the development of shop drawings by the fabricator.

- Structural Design: Delivered a robust and flexible structural design, customized to meet the unique demands of the project.

- Collaboration and Support: Ensured seamless project execution by maintaining active collaboration with BEUMER and other onsite contractors.

- Project Management: Upheld strict adherence to project schedules and quality standards through diligent construction support.

The Overland Conveyor Upgrade project at Warrior Met Coal, Inc. stands as a testament to SAXUM’s expertise in providing end-to-end engineering and construction support solutions, ensuring the successful delivery of a functional and efficient conveyor system by BEUMER.

Expert Construction Management for Minera Santa Cruz’s Capacity Expansion Project

Minera Santa Cruz (MSC) was established in 2001 through a joint venture between Hochschild Mining and Minera Andes (now McEwen Mining) to explore and develop the San José Mine. Located 50 kilometers from Perito Moreno in Santa Cruz Province, the San José deposit is a low-sulfidation epithermal system with gold and silver-enriched quartz veins in the northwest of the Deseado Massif.

MSC is undertaking a project to expand the plant's capacity from 1,700 tons per day (TPD) to 2,000 TPD. The expansion includes implementing a regrinding circuit with a new vertical mill and associated equipment.

During Q1 of 2024, SAXUM provided specialized engineering support for MSC through a Feasibility Study to achieve the expansion goal of 2,000 TPD. This included evaluating downstream circuits for flotation, thickening, and concentrate filtering, as well as identifying potential bottlenecks in pumps, piping, and discharge boxes to ensure smooth operation at the increased capacity.

Additionally, SAXUM provided MSC with a professional project management assistance to establish a Project Management Team. This team supported MSC’s corporate structure in managing the plant's capacity expansion, emphasizing strict adherence to timelines, cost controls (CapEx), and quality standards during all phases of the project.

Finally, a key component of this initiative was the inclusion of a highly specialized Construction Management team with expertise in mining projects to oversee and coordinate all works. MSC selected SAXUM to perform the construction management, leveraging their extensive experience and proven expertise in managing complex mining projects. The team’s focus was on meeting the project’s stringent deadlines, maintaining budget efficiency, and ensuring quality throughout the construction and commissioning stages.

Our specialized Construction Management Team offered a full suite of services, ensuring seamless project execution:

- Construction Management: Oversight and coordination of all project activities.

- Supervision of Field Activities: Ensuring on-site compliance with engineering specifications.

- Project Control: Monitoring progress and maintaining alignment with the project’s schedule and budget.

- Contract Administration: Managing contractual obligations effectively.

- Commissioning Stage Support: Facilitating system integration and operational readiness.

- Contract Closure: Finalizing all aspects of the construction and documentation processes.

A critical focus of the SAXUM team was ensuring the safe closure of construction activities, with all works completed incident-free. Additionally, we prioritized the successful conclusion of construction and management contracts, supported by comprehensive documentation and meticulous compliance with project requirements.

Meet our Senior Mechanical Engineer, Andrés Eyherabide

Meet Andrés Eyherabide, SAXUM’s Senior Mechanical Engineer, whose expertise and leadership drive innovation across our projects. With over 12 years of experience in cement industry technologies and a proven track record in mechanical and process engineering, Andrés has become a key figure in delivering high-quality solutions for complex challenges. His dedication and technical acumen make him an invaluable part of the SAXUM team.

His professional journey includes a pivotal tenure with ThyssenKrupp Polysius, a global leader in cement technology, where he excelled in mechanical engineering, plant design, and process engineering. During his time there, Andrés contributed to major projects in Argentina and beyond, gaining hands-on experience through site visits, equipment design, layout development, and technical calculations. His work in Germany further solidified his role as a senior consultant, specializing in conceptual engineering and CAPEX estimation.

At SAXUM, Andrés has demonstrated exceptional leadership and technical expertise, guiding projects from concept to completion with a focus on cost and time efficiency. His contributions include detailed engineering for innovative systems such as an alternative concrete pump, a hydrogenerator performance study, and a frac sand management system for wet materials. Over the past two years, he has led process, plant design, and mechanical engineering efforts for diverse projects, including:

- Cement Grinding Facilities: Leading the engineering for two significant grinding plants.

- Material Handling Systems: Developing solutions for silos, dedusting systems, kiln feed improvements, and raw mill recirculation in the cement industry.

- Frac Sand Handling Solutions: As lead engineer for a fracking sand company, developing advanced handling solutions for two years.

Latest news

- The Story Behind the Partnership – SAXUM/Lycopodium 6 August, 2025

- SAXUM´s Newsletter Issue #251 – May 2025 21 May, 2025

- SAXUM Joins Forces with Lycopodium 18 February, 2025

- SAXUM´s Newsletter Issue #242 – December 2024 9 December, 2024

- SAXUM´s Newsletter Issue #241 – May 2024 1 May, 2024

- SAXUM´s Newsletter Issue #232 – Dec 2023 14 November, 2023

Categories

- Articles (1)

- Connection (13)

- Events (2)

- News (11)

- Sin categoría (7)

You must be logged in to post a comment.